Ensuring Safety in PNEUMATIC & HYDROSTATIC testing

Pressure Testing Safety Enclosures

Pressure testing procedures can release high-impact energy in the form of ruptured components and high-velocity fragments, making engineered shielding critical to a safe testing environment. Our overpressure protection enclosures are purpose-built to safeguard personnel and equipment during these types of procedures.

Discover how our Shielded Enclosures are designed to protect your personnel and machinery and why you should include them in your pressure testing equipment.

The Critical Role of Engineered Enclosures

Hydrostatic & Pneumatic Pressure Test Safety

Engineered enclosures are vital in mitigating the risks associated with overpressure events. These events, often occurring during testing or operational phases, can lead to catastrophic failures if not properly managed.

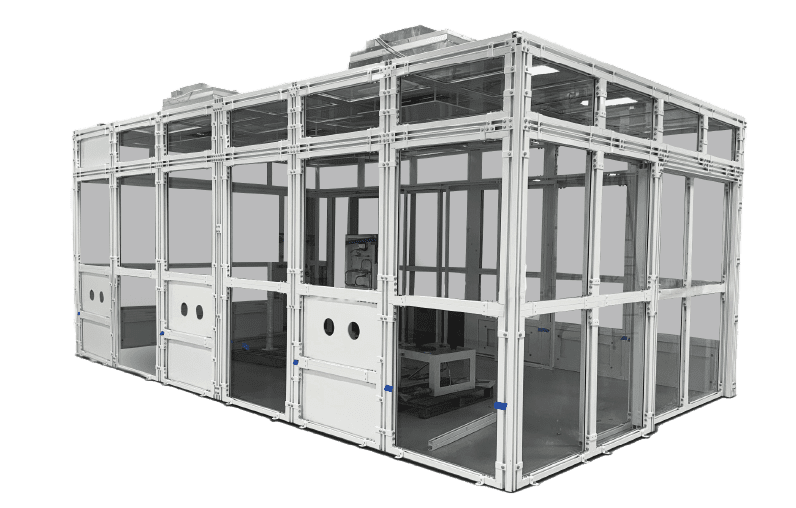

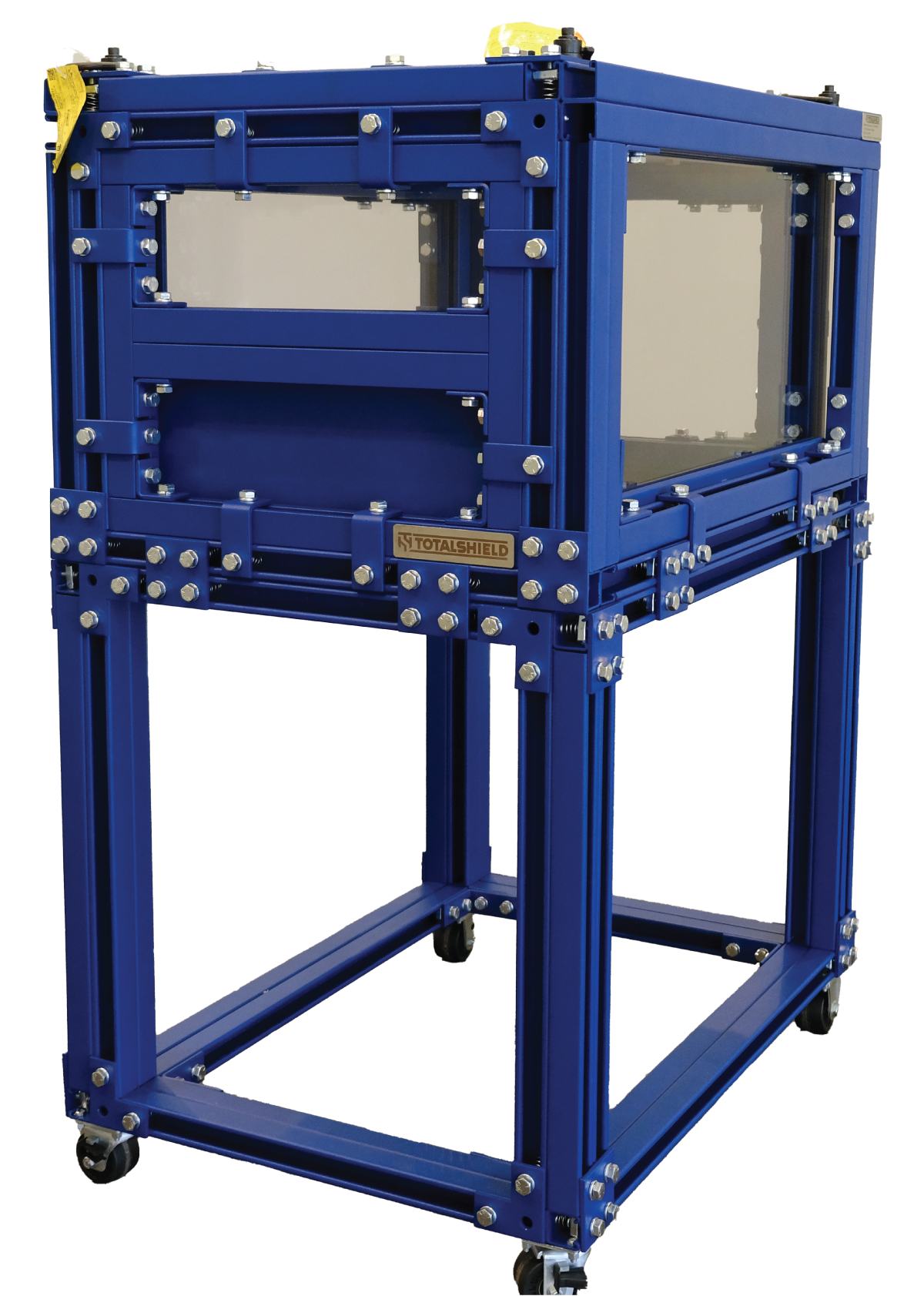

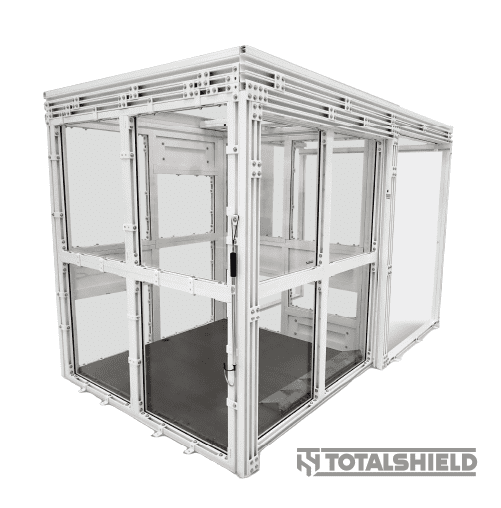

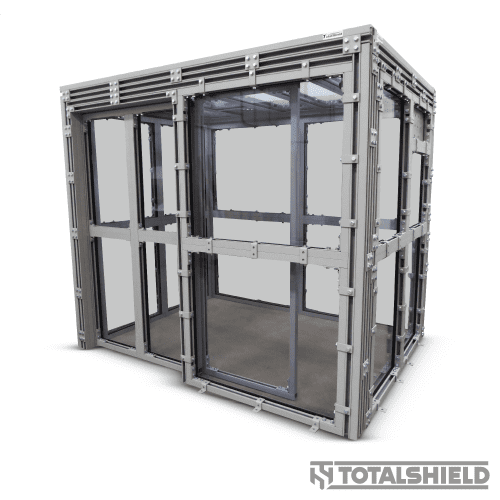

Built with clear, blast-rated panels and our proprietary modular framing system, TotalShield’s pressure testing enclosures allow full visibility while providing robust containment. Whether you’re testing valves, pipes, vessels, or other pressurized components, our shielded enclosures are designed to absorb and deflect the forces generated by overpressure events.

Risks of Pressure Testing

Pressure testing poses significant risks if not conducted with adequate protection. The sudden release of pressure can result in explosive forces that can lead to equipment destruction, serious injuries, and costly downtime.

These incidents often stem from:

- The presence of air pockets during hydro tests

- Improper substitution of pneumatic for hydrostatic testing

- Rapid pressurization without proper monitoring

- Failures in pressure relief systems

Overpressure Protection Enclosures Features

Our enclosures are designed with advanced materials to withstand extreme pressure conditions, ensuring maximum safety during testing.

Robust Containment

Customizable Designs

- Single-door or wall configurations

- Full shielding rooms

- Benchtop enclosures

- Mobile cart-integrated enclosures

- Hinged or sliding access panels

- Integrated vented panels for pressure relief

- Anchored floor mounts for fixed test bays

- Ceiling

Clear Blast-Rated Panels

Integrated Safety Features

They can include lighting integration, fume extraction, fire impression system integration, ventilation, ballistic blanket integration, and more.

Explore Our Enclosures in Action

Our Past Projects

Considerations for Pressure Testing Shielding

TotalShield pressure testing enclosures are not a replacement for procedure safety, they’re a complement to it. We work closely with engineers, EHS teams, and plant managers to ensure each unit supports the broader safety protocols you already have in place.

Whether you’re performing a hydrotest or pneumatic pressure test or pressure vessel testing, our engineering team will design the shielded enclosure you need.

Why Engineers Choose TotalShield

TotalShield enclosures give you a critical layer of protection that doesn’t disrupt your workflow but drastically reduces your exposure to high-risk scenarios.

Our over 20 years of experience spreads over industries such as:

- Oil and Gas

- Aerospace

- Automotive

- Manufacturing

- Green Energy

- Test Labs

That’s why leading engineers trust TotalShield as an essential part of their pressure testing safety strategy.

You can also read our Pneumatic Pressure Testing Handbook.

Protect What Matters

Your people. Your equipment. Your facility. When pressure testing is part of your operation, overpressure protection isn’t optional, it’s essential.

With TotalShield’s custom-engineered containment enclosures, you can maintain testing precision without compromising safety. We help you meet industry codes, reduce liability, and foster a culture of operational excellence.

Let’s build a safer testing environment together 🛡️