Clear Blast Rooms | High-Impact Protection

Shielding Rooms

Level up your business’s protection protocols with TotalShield’s custom clear shielding rooms.

Walk-In Testing Chambers

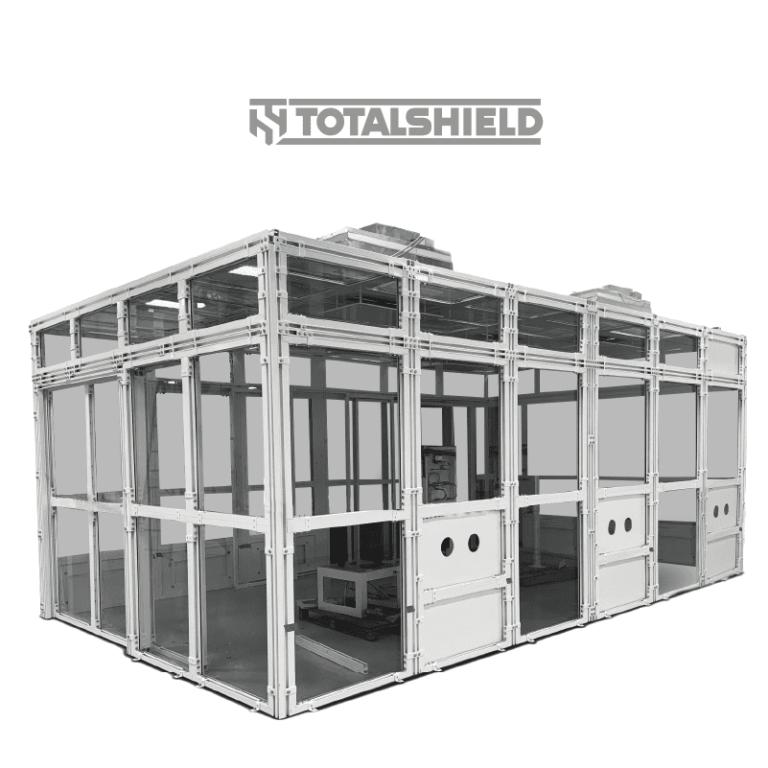

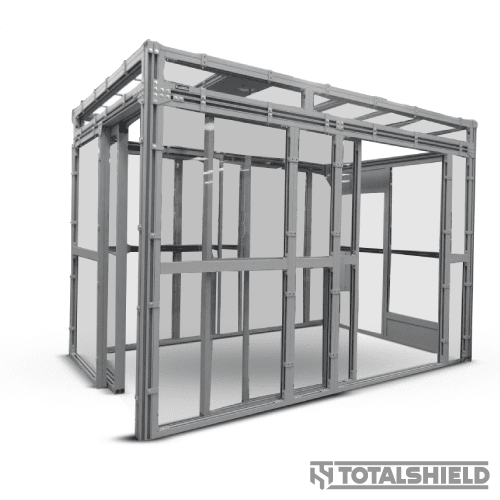

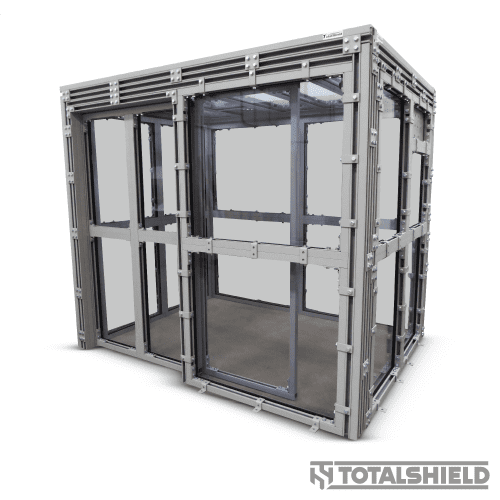

Our Shield Rooms are our largest enclosures, specifically designed to contain blast and protect personnel and machinery from potential explosions, pressure release, or shrapnel.

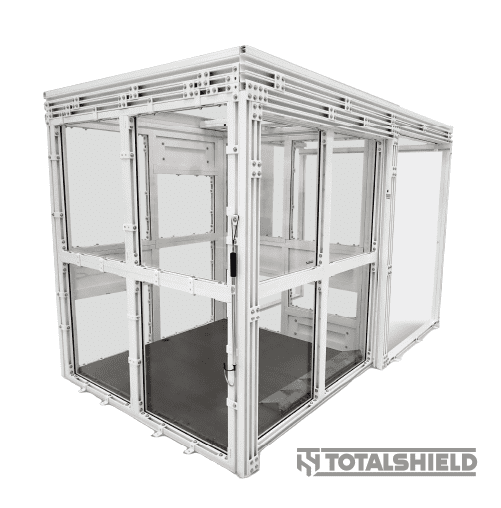

Crafted with clear impact-rated panels and our proprietary modular steel and aluminum framing system, our walk-in chambers are used for a wide range of applications: pressure testing, ballistic protection, industrial equipment containment, battery testing, and more.

All our shielding products are custom-made to seamlessly integrate into your facility and workflow.

Features

Custom-fitted to your facility and workflow

Thoroughly tested offering blast, Level A Ballistic, and Level I to III forced entry protection

Doors, retractable roofs, access panels, ventilation, Kevlar blanket integration, and more

Engineered to your energy impact threat level

No building permits required

Interface panels allow utilities, hose, wire pass-throughs

Versatile configurations: complete freestanding room or single walls

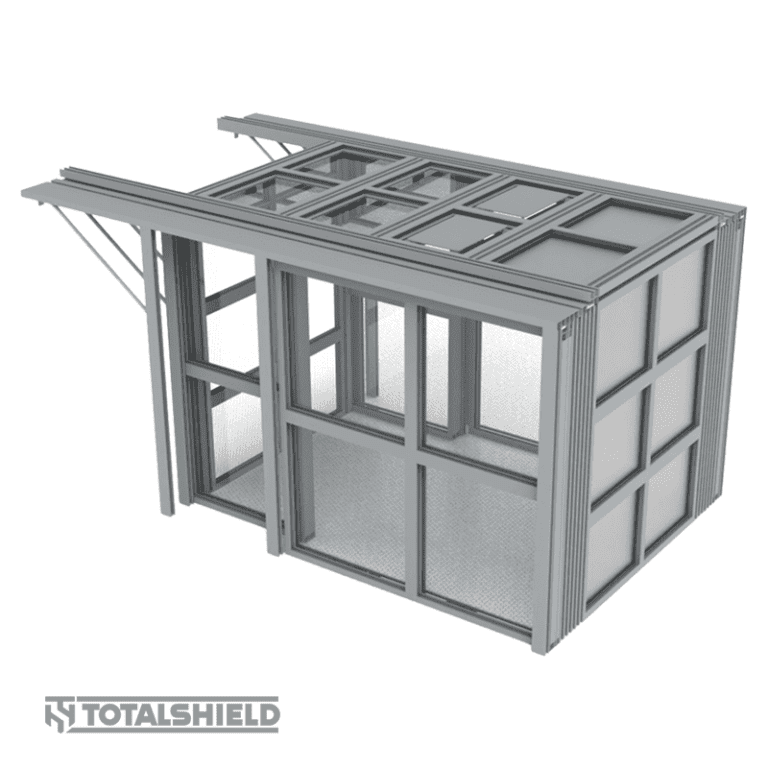

Fixed or retractable ceiling available

Take a Look at Our Past Projects

- Walk-in Chambers

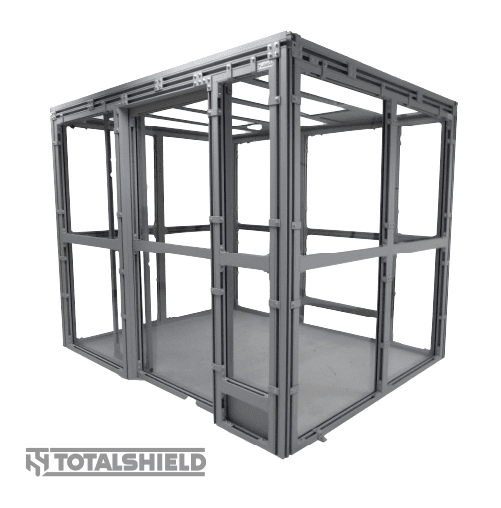

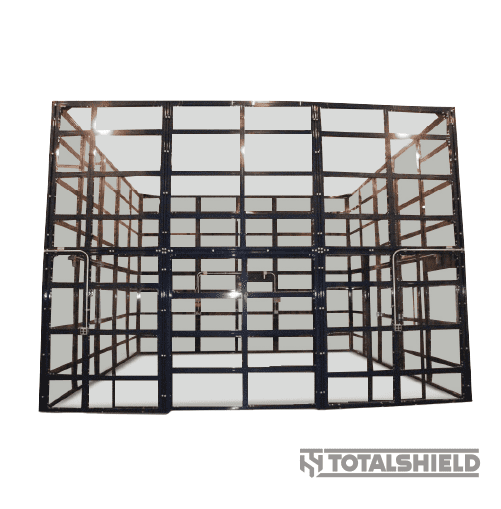

Modular Framing Technology

Our modular framing system offers custom configurations to suit your needs—install them as a complete room or as individual walls to divide work areas.

Transparent Walls

Our transparent blast-rated panels provide a 360-degree clear view. This allows tests and operations to be monitored safely outside the room, and failures can be detected quickly.

Portable Enclosures

Our blast-resistant enclosures’ modular design offers easy portability, allowing you to assemble, move, or relocate them without the costs of permanent structures or facility modifications.

Engineer Support

We always provide a detailed assembly guide with step-by-step instructions and video support calls with our engineers. Onsite installation assistance is also available.

Custom Shielding Enclosures

SEAMLESS SOLUTIONS

Whether you need a walk-in safety chamber or a bay station, our engineers will work with you to design a custom-fitted solution for your facility and workflow.

With TotalShield you can have:

- Free-standing rooms with sliding access doors

- Single walls

- Room dividers

- Corner barriers

- Walk-in chambers

- Detachable mobile walls for access

- Retractable roof for overhead crane access

- And more

Talk to us and tell us what you require.

Blast Shielding Room Specifications

- Polycarbonate sheets

- Bullet-resistant glass

- Ceramic panels

- Composite panels

- Fiberglass panels

- Aluminum and steel framing

- Steel plates

- Your specific threat determines the material thickness used

- We use ballistic hard coat polycarbonate thickness of 1/2”, 3/4”, and 1.25”

- Glass-clad polycarbonate for special applications sugh as high heat is also available

- Free-standing room with sliding access doors

- Single walls

- Room dividers

- Corner barriers

- Fixed or retractable roof

- Movable wall segments

We deliver our shielding rooms partially assembled; installation is easy. Ask for our onsite installation supervision service.

- Hydrostatic pressure testing

- Pneumatic pressure testing

- Burst testing

- Ballistics

- Rotating machinery

- Large battery system testing

- Flammable or explosive gas handling

- Hazardous machine containment

- Hazardous operation shielding

- Barrier separation of a hazardous area

- High-velocity projectile containment

- High-heat or flame threats

Not sure of what you need? Get help from our engineers team

Common Industry Applications

- Hydrostatic testing

- Ballistics

- Machinery containment area

- Hydrogen electrolyzer safety

- Large battery system testing

- Pneumatic testing

- Explosive operations

- Rotating equipment

- Hydrogen fuel cell enclosures

- Explosive gas handling

- Burst testing

- Projectile Containment

- Hazardous operation shielding

- Pressure testing

Related Products

GET A QUOTE

Let us know your business needs and our engineering team will start designing your blast room.

If you prefer, you can also give us a call:

1 (844) 882-5278