We have already discussed ballistic resistance standards and how they apply to polycarbonate ballistic performance. Like ballistic testing, there are a variety of standards for explosive resistance for polycarbonate enclosures.

Explosion-resistant or “explosion-proof” enclosures must be tested for different blasting scenarios. Let’s check the standards they need to comply with.

Explosion Protection Standards

The main standard used for explosion containment of windows and doors in buildings was established by the General Services Administration (GSA) in the public document GSA-TS01-2003 “US General Services Administration Standard Test Method for Glazing and Window Systems Subject to Dynamic Overpressure Loadings.” Its purpose is to determine the protective level of windows and doors on a building in the event of an outside explosion.

According to the introduction of this test methodology document:

“This test standard is intended to ensure an adequate measure of standardization and quality assurance in the testing of window systems including but not limited to glazing, sealants, seats and seals, frames, anchorages and all attachments and/or secondary catcher or restraint mechanisms designed to mitigate the hazards from flying glass and debris. This standard is the sole test protocol by which blast-resistant windows and related hazard mitigation technology and products shall be evaluated for facilities under the control and responsibility of the US General Services Administration (GSA).”

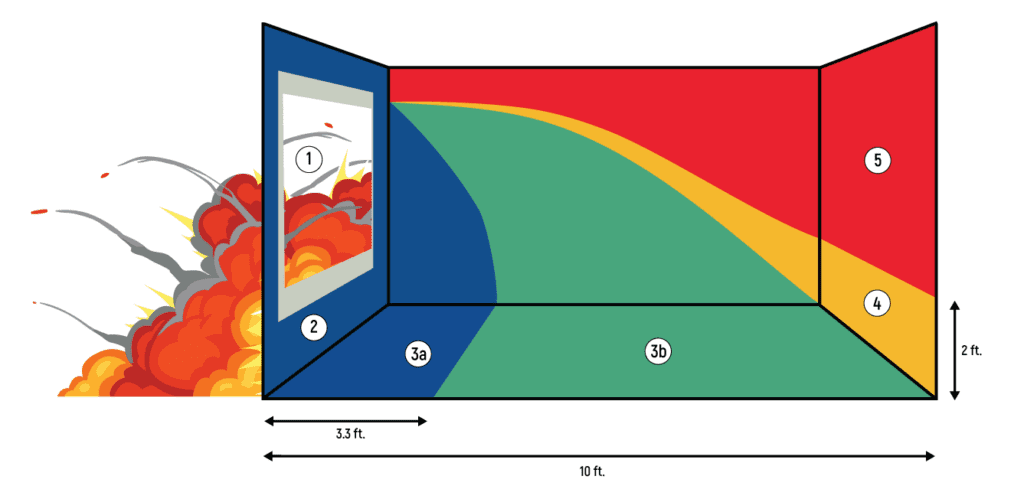

To give you an idea of how the GSA illustrates its methodology, please look at the following image:

The image represents a ten-foot-long room. An explosion happens outside the room, impacting the window, potentially breaking the window, and sending fragments into the occupied space.

The following table shows the blast resistance levels specified by the GSA, with a rating of “1” and a protection level of “Safe” as defined as “No visible damage to glazing or frame.”

| PERFORMANCE CONDITION | PROTECTION LEVEL | HAZARD LEVEL | DESCRIPTION OF WINDOW GLAZING RESPONSE |

|---|---|---|---|

| 1 | Safe | None | Glazing does not break. No visible damage to glazing or frame |

| 2 | Very High | None | Glazing cracks but is retained by the frame. Dusting of very small fragments near sill or on floor acceptable. |

| 3a | High | Very Low | Glazing cracks. Fragments enter space and land on floor no further than 3.3 ft. from the window. |

| 3b | High | Low | Glazing cracks. Fragments enter space and land on floor no further than 10 ft. from the window. |

| 4 | Medium | Medium | Glazing cracks. Fragments enter space and land on floor and impact a vertical witness panel at a distance of no more than 10ft. from the window at a height no greater than 2 ft. above the floor. |

| 5 | Low | High | Glazing cracks and window system fails catastrophically. Fragments enter space impacting a vertical witness panel at a distance of no more than 10 fr. from the window at a height greater than 2 ft. above the floor. |

One limitation of the GSA-TS-01-2003 testing protocol is that the actual testing load for some specifications is classified and is not included in the publicly available test documentation. While some vendors claim their product meets a GSA-TS-01-2003 performance condition or test level, they must also disclose the explosive force and blast impulse or duration for the claims to have any context.

The GSA does provide a five-level classification of the window performance for building types based on their level of security. The following table explains this classification:

| BUILDING CLASSIFICATION | GSA DESCRIPTION | BLAST LEVEL AND WINDOW SURVIVABILITY |

|---|---|---|

| A | No window protection is needed – Standard construction is acceptable | N/A |

| B | Requires the use of laminated glass, applied film, or tempered glass for non-blast protection (i.e., wind) | N/A |

| C | Medium-security building | 4 psi @ 28 psi-msec, minimum performance condition 3b |

| D | High-security building | 10psi @ 89psi-msec, minimum performance condition 3b |

| E | Very high-security building | Classified |

Explosion Resistance of Polycarbonate by Thickness

Some polycarbonate manufacturers have designed and conducted their own explosive blasting tests. In the table below, we have summarized data from multiple manufacturers based on research conducted by TotalShield. This will give you a general sense of the explosive-resistance qualities of polycarbonate for various thicknesses.

| NOMINAL THICKNESS (inches) | ACTUAL THICKNESS (inches) | WEIGHT lbs/sqft | EXPLOSIVE OVERPRESSURE |

|---|---|---|---|

| .375” | .390″ | 2.4 | Not Rated |

| .500” | .522″ | 3.3 | Approximately 100 lbs of TNT at 50 ft Overpressure: 20 psi Duration: 7 msec |

| 0.75” | .780″ | 4.9 | Approximately 150 lbs of TNT at 50 ft Overpressure: 28 psi Duration: 7 msec |

| 1” | 1.05″ | 6.5 | Approximately 4300 lbs of TNT at 115 ft Overpressure: Above 40 psi and below 60 psi Duration: 15 msec |

| 1.25” | 1.30″ | 8.1 | Approximately 4300 lbs of TNT at 115 ft Overpressure: Above 40 psi and below 60 psi Duration: 15 msec |

⚠️ Please note this data is provided for illustrative purposes only. Actual data from the manufacturer or qualified third-party testing organizations should be relied on for ascertaining the actual explosive resistance of a given polycarbonate sample.

Overpressure or blast overpressure is caused by a shock wave over normal atmospheric pressure. In the case of an explosion, overpressure is the almost instantaneous rise from atmospheric pressure to a maximum overpressure as the explosive force expands.

As the table above shows, 1.25” laminated polycarbonate can withstand blast overpressures of between 40 psi and 60 psi. The variance is due to the differences in manufacturers’ published testing documents. However, this range represents a large amount of pressure, even at the low end of the estimate of 40 psi.

Blast Overpressure Effects on Humans

After checking the last table, you might be wondering how much pressure is 40 psi.

The following table from the CDC provides the following information on the damage caused by overpressures on the human body and various structures. The data was obtained through weapons tests and blast studies, and it gives some guidance on the possible effects of mine explosions on miners.

| PEAK OVERPRESSURE | MAX. WIND SPEED | EFFECT ON STRUCTURES | EFFECT ON THE HUMAN BODY |

|---|---|---|---|

| 1 psi | 38 mph | Window glass shatters | Light injuries from fragments occur |

| 2 psi | 70 mph | Moderate damage to houses (windows and doors blown out and severe damage to roofs) | People injured by flying glass and debris |

| 3 psi | 102 mph | Residential structures collapse | Serious injuries are common, fatalities may occur |

| 5 psi | 163 mph | Most buildings collapse | Injuries are universal, fatalities are widespread |

| 10 psi | 294 mph | Reinforced concrete buildings are severely damaged or demolished | Most people are killed |

| 20 psi | 502 mph | Heavily built concrete buildings are severely damaged or demolished | Fatalities approach 100% |

According to Glasstone and Dolan:

“The human body can survive relatively high blast overpressure without experiencing barotrauma. A 5 psi blast overpressure will rupture eardrums in about 1% of subjects, and a 45 psi overpressure will cause eardrum rupture in about 99% of all subjects. The threshold for lung damage occurs at about 15 psi blast overpressure. A 35-45 psi overpressure may cause 1% fatalities, and a 55 to 65 psi overpressure may cause 99% fatalities”.

The table above also shows the maximum wind speed associated with the overpressure.

In mine explosions, as in war-related explosions, the blast wind resulting from the blast overpressure leads to injuries and fatalities. The human body may be thrown violently into objects and receive blunt force trauma; conversely, large objects may be thrown into persons resulting in crush injuries, or else projectiles launched by the blast wind may penetrate the body.

The susceptibility of personnel to blast effects depends on their proximity to nearby objects and possible projectiles. Miners standing in the open and away from projectiles may survive higher blast overpressures than those standing near a solid wall or object. Personnel sitting within the confines of machines may receive some protection from blunt force trauma and projectiles.

It is important to note that while this research was conducted for mining activities, it is also relevant to many of our customers. For example, an industrial manufacturer who is conducting pneumatic pressure testing could potentially expose their staff to similar dangers in the event of explosive failure.

While it is impossible to determine the exact correlation between blast wave overpressure and fatality rate for personnel in an active underground mine, the above data in the table provides helpful guidance.

Blast Overpressure Effects on Polycarbonate Structures

Explosive testing of polycarbonate is difficult because, unlike the point impact experienced during a ballistic impact, a pressure wave acts on the polycarbonate uniformly. This puts much more stress on the framing or support structure holding the polycarbonate panel being tested. If care is not taken to secure the panel properly, then the first mode of failure is often in the frame rather than the polycarbonate.

For example, in testing performed by the University of Kentucky on ½-inch polycarbonate, a 900-gram explosive charge at 77 ft. caused the failure of the mounting screws holding the polycarbonate but had a minimal effect on the polycarbonate itself. Under this test, a peak overpressure of 10.454 psi at an impulsive of 120.923 psi-msec was achieved. The test author concluded that:

It must be noted that the glazing system itself did not fail, rather the screws attaching the framing to the attachment points failed. Had they not failed, it is uncertain how much more loading the glazing system may have been able to withstand.

This highlights a challenge of manufacturing an explosive-resistant material: it is not enough for a single component to resist the explosive blast overpressure. The entire product must be engineered to be resistant to the rated overpressure.

That is why at TotalShield, we have spent over 20 years developing a system of aluminum and steel framing, energy-absorbing gasketing, and assembly that has been tested under a range of ballistic and explosive conditions to avoid failure modes such as panel pull-out.

Polycarbonate is highly resistant to explosive blasts. However, determining how much overpressure it can resist without failing is complicated.

The information manufacturers provide can vary based on the historical testing they have performed and what they will disclose. The table below provides a summary of the testing published by leading US-based manufacturers of polycarbonate. It is important to note that these tests are only applicable to the polycarbonate panel itself and exclude mounting and framing considerations.

| POLYCARBONATE THICKNESS (inches) | BLAST LEVEL | STANDARD/TEST METHOD | PROTECTION LEVEL |

|---|---|---|---|

| .525” | 6 psi, 42 psi-msec | UFC 4-010-01 ASTM F 1642 GSA-TS01-2003 | GSA Performance Condition 1: Safe Hazard Level: None |

| .525” | 10 psi, 89 psi-msec | UFC 4-010-01 ASTM F 1642 GSA-TS01-2003 | GSA Performance Condition 2: Very High Hazard Level: None |

| 1.1” | Up to 40 psi overpressure | ASTM F 1642 | Passed |

| 1.1” | 10 psi, 89 psi-msec | GSA / ISC TS201 – Building D | GSA Performance Condition 2: Very High Hazard Level: None |

| 1.1” | 21 psi | ASTM F 1642 | No Hazard |

| 1.3” | Above 40 psi | GSA / ISC TS201 – Building E | Classified |

The only way to properly ensure that an “explosion-proof” enclosure (remember, the correct term is explosion-resistant) or an explosion containment room will provide adequate levels of safety is to conduct third-party testing under proper laboratory conditions.

For example, the following video shows a test we conducted with a third-party testing partner to verify the containment of an explosion associated with a sodium hypochlorite generator:

TotalShield employs not just data from manufacturers and federal agencies but also the information we have collected over 20 years in our blast testing archive. In addition, we conduct specific explosive tests for our customers to verify that a system can withstand a customer-specific explosive failure scenario.

If you need help engineering your explosion containment enclosure or protective barrier, do not hesitate to contact us.