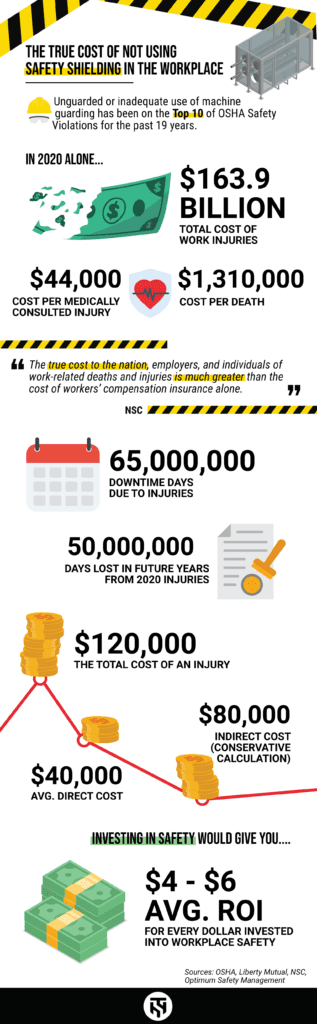

Workplace injuries can be devastating to both the employee and the employer. Most workplace injuries are preventable with the right training and equipment. Safety shielding is a crucial element that ensures workplace safety. Unfortunately, some businesses underestimate the cost of not using safety shielding around their machinery or equipment. This can result in approximately 18,000 amputations, lacerations, and other injuries to personnel operating machinery annually due to inadequate safeguarding or unguarded machinery.

In this blog, we’ll dig into the costs of not using machine shielding, including expenses related to workplace injuries and the benefits your business can gain by investing in safety measures.

For a quick overview, you can click on the infographic below. For more in-depth information, continue reading.

The cost of work injuries

In 2020, American businesses incurred over $160 billion in costs due to work injuries, as reported by the National Safety Council (NSC). This includes various expenses, such as:

- medical and administrative expenses

- employers’ uninsured costs

- time lost

- time spent on investigations

- damage to machinery

- fire losses

- etc.

Furthermore, work injuries can also lead to decreased morale and increased turnover rates, further elevating business costs.

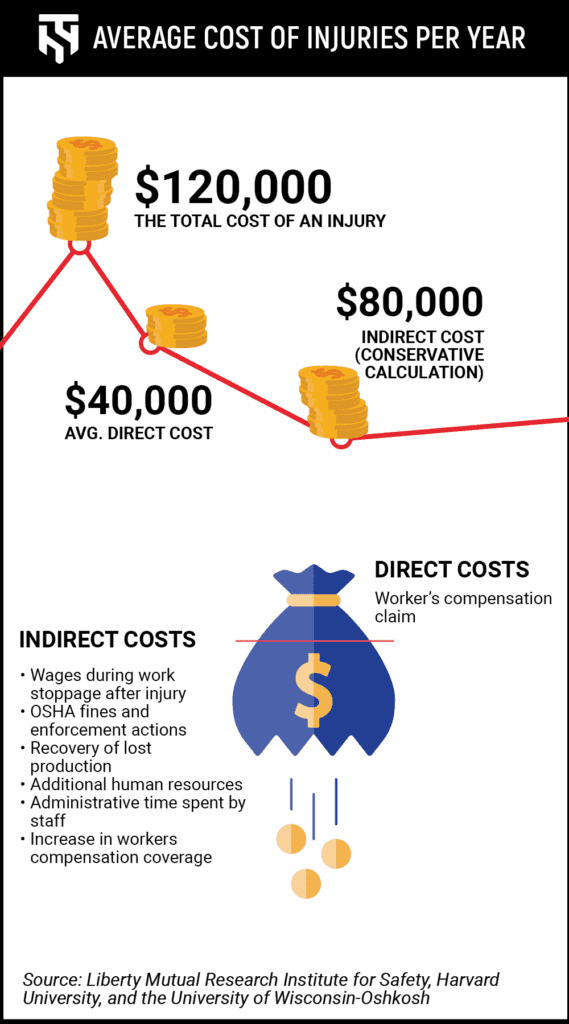

Workplace injuries come with two types of costs: direct and indirect.

Direct costs: around $40,000 annually

The direct costs of not using safety shielding include medical bills, rehabilitation costs, and workers’ compensation payments. The NCS estimates the average cost of a work-related injury in the United States as $42,000 per accident.

Indirect costs: around $80,000 annually

According to a study carried out by the Liberty Mutual Research Institute for Safety, Harvard University, and the University of Wisconsin-Oshkosh, indirect costs amounted to approximately $2.12 for every dollar spent on direct costs.

As you can see, the indirect costs, though less apparent, are significantly higher, encompassing various expenses:

- Wages during work stoppage after injury

- OSHA fines and enforcement actions

- Recovery of lost production

- Human resources

- Administrative time spent

- Increase in insurance coverage

According to Optimum Safety Management, a conservative estimate of indirect costs is around $80,000, giving a total cost per workplace injury of $120,000 when both direct and indirect costs are considered.

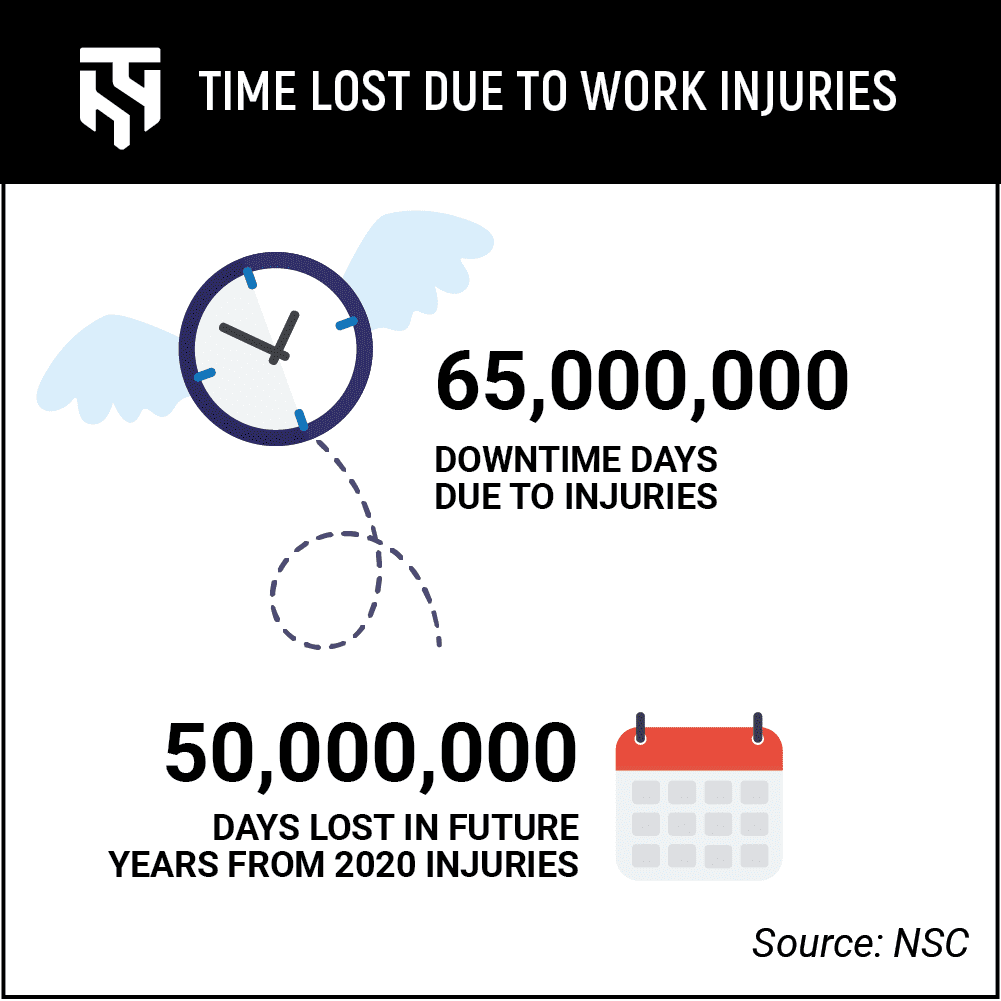

Time lost due to work injuries

When a worker is injured, they may require time off work to recover. The number of lost days can vary depending on the severity of the injury.

According to the Bureau of Labor Statistics (BLS), the median number of days away from work for a nonfatal workplace injury or illness was nine days in 2020. The median number of days away from work for severe injuries was 28 days. These lost days can result in significant productivity losses for the business, leading to missed deadlines and project delays.

The NSC estimated a total of 99,000,000 days lost due to work-related injuries for 2020, including those resulting from previous years’ injuries. 2020 injuries could account for up to 50,000,000 lost days in the coming years.

Furthermore, when workers are off work due to injuries, the business may need to hire temporary workers or pay overtime to other employees to cover the workload, increasing expenses for the company and reducing overall productivity.

Workplace Safety Investment Return

Investing in safety shielding can have a substantial Return on Investment (ROI). According to OSHA, businesses can save $4 to $6 for every $1 invested in workplace safety. This includes savings from reduced injuries, increased productivity, and decreased insurance costs.

In addition, OSHA and the Voluntary Protection Program report that over 500 workplaces among 180 industries see savings of over $110 million each year because their injury rates are 50% below the average for their respective industries.

Machine shielding methods

We’ve gone through the cost of work injuries, now let’s take a look at some machine shielding methods that can help prevent workplace injuries.

- Hard guards, which are physical barriers that prevent contact

- Safeguarding devices, such as two-handed controls, gates, or pullback or restraint straps

- Automated feeding and ejection mechanisms

- Polycarbonate enclosures

- Electronic presence-sensing devices

- Machine location or distance to remove the hazard from the operator’s work area; and

- Miscellaneous aids that protect operators and people in the work area, such as:

- shields to contain flying debris;

- protective guide tools

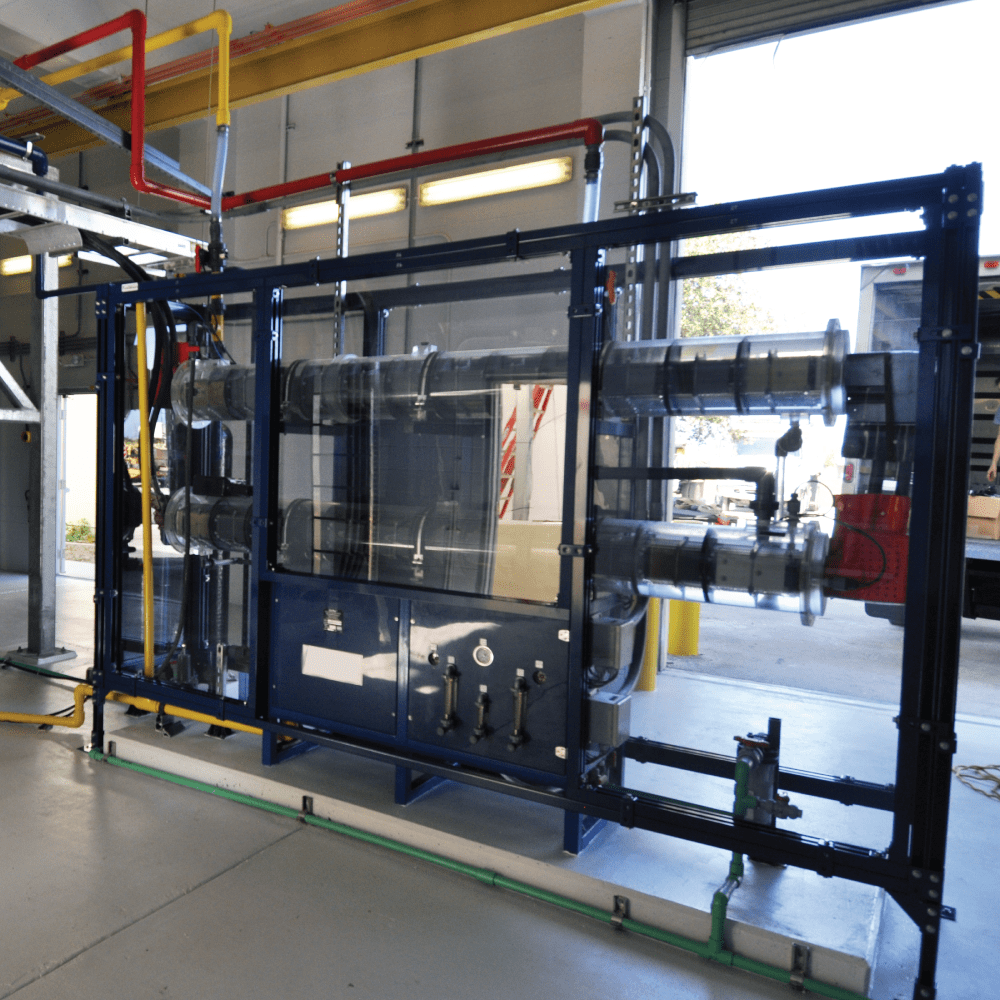

TotalShield’s polycarbonate shielding enclosures are blast and ballistic-resistant, providing personnel with a clear view of the machine while still offering protection from hazardous scenarios. Our enclosures are particularly useful if your equipment requires monitoring, regular maintenance, or adjustment.

All our machine shielding enclosures can be customized to fit the specific needs of the machine and work process. Some of the features we’ve included for previous customers include sliding doors, ceiling panels, vent integration, and more.

Compared to traditional metal machine guards, TotalShield’s enclosures are lightweight, impact-resistant, and easier to install and maintain. While polycarbonate shielding may be more expensive than metal guards, it can provide long-term cost savings by reducing the risk of workplace injuries and associated costs.

Machine guards guidelines

When looking for your machine shielding, make sure to comply with OSHA’s guidelines. All types of machine guarding must:

- Prevent contact between dangerous moving mechanical parts and body parts and clothing

- Remain firmly secured. Guards and safety devices should be made of durable material

- Protect from projectiles or flying shrapnel

- Create no new hazards

- Not interfere with work or stop personnel from doing their jobs

- Allow for safe lubrication, and, allow operators to provide maintenance to the machine without removing the guards

Protect your workers with safety shielding

Investing in safety shielding is crucial for businesses looking to prioritize workplace safety and minimize costs associated with work injuries and equipment damage.

At TotalShield, we’ve been providing customized machine guarding solutions for over 20 years, using our expertise in designing and manufacturing shielding enclosures to create solutions tailored to your unique needs.

Contact us today to start building a safer workplace for your employees.