When designing our explosion-resistant enclosures, our customers might not be able to provide all the necessary information. If that’s the case, we then use a TNT equivalent for the explosive that will be used.

This blog post will explore how we apply TNT equivalence to our blast-resistant enclosures design.

What is TNT equivalent?

Well, that’s a loaded question (pun intended), but first things first. TNT is an abbreviation for trinitrotoluene. This solid organic nitrogen compound is the most commonly known and commercially available explosive.

Now, when we talk about the TNT equivalent, we’re actually referring to the energy released in an explosion expressed in units of mass. Put simply, a TNT equivalence is a convention that allows us to compare the energy released from joules to grams.

Let’s say there’s an explosion that releases 5,000J of energy into the atmosphere. If we want to determine the amount of TNT in grams or kilograms needed to match the energy released, then we would use a TNT equivalent.

How is TNT equivalence determined?

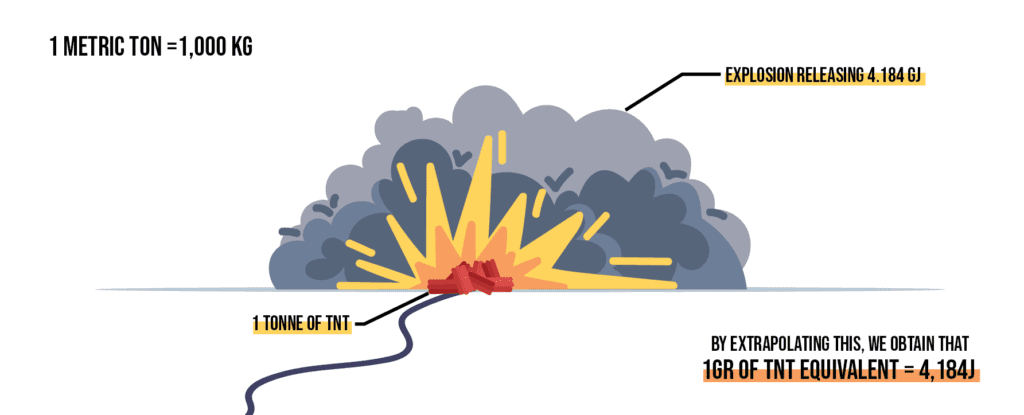

When TNT or any type of explosive is detonated, it must first be weighed to determine the energy released in its explosion. The TNT equivalent is measured in metric tons, also known as “tonne,” which is a metric unit of mass. 1 metric ton equals 1,000 kilograms.

If we detonate 1 tonne of TNT, the energy release would be equal to 4.18GJ. Extrapolating this information, we can determine that 1 gram of TNT equivalent equals 4,184J.

Based on the example previously given, a 5,000J explosion or blast would equal approximately 1 gram of TNT.

It is important to note that TNT equivalents are established by several empirical tests which require detonating the explosive and then measuring its power output using a number of different testing methods and evaluation criteria. For this reason, there may be some variance between published TNT equivalents based on the testing methodology used.

The Relative effectiveness factor, or R.E. factor, relates an explosive’s demolition power to that of TNT in units of the TNT equivalent/kg (TNTe/kg). The R.E. factor is the amount of TNT to which 1 kg of an explosive is equivalent; the higher the R.E., the more powerful the explosive. This enables engineers to use different explosives when calculating blasting equations designed specifically for TNT.

The table below shows some common explosives and their TNT equivalent and Relative Effectiveness factor. As the table shows, nitroglycerin is much more explosive than TNT, which is in turn much more explosive than black powder. Higher TNT equivalents also correlate to higher RE factors.

| Explosive | TNT Equivalent | Relative Effectiveness (RE) |

|---|---|---|

| Nitroglycerin (Used in Dynamite) | 1.48 | 1.54 |

| Semtex (Plastic Explosive) | 1.25 | 1.35 |

| TNT | 1.00 | 1.00 |

| Amatol (Mining Explosive) | 0.59 | 0.91 |

| Black Powder (Firearms) | 0.43 | 0.55 |

How we use TNT equivalence in blast containment design

We use TNT equivalence to determine the required thickness of polycarbonate shielding for a customer’s unique application. The requirements in a TNT equivalent are the first parameters needed when designing a blast-resistant enclosure.

Some customers cannot share the specific explosive used within the containment system. In these situations, they can provide us with the TNT equivalent.

Once we have this data, we then consider the location of the blast event relative to the explosion containment enclosure. As our founder, Keith Snyder, notices, “explosive blasts are spatially dependent.” In order to determine the impact energy exerted on our shield panels during a blast event, we consult our blast testing archive or do a blast analysis if there’s no data available.

This is how we can determine the maximum impulse and impact energy exerted on a shield panel based on the explosive load and the location of the explosive being detonated within the containment system. Once we have determined the maximum energy exerted on the nearest surface, we can determine the required level of protection within our polycarbonate shield panels.

In 2016, we designed a shielded room for a customer who wanted to conduct repeated detonated loads in the room. These were the blast requirements:

- A maximum repeated explosive load of 100g TNT equivalent (418,400 J)

- A maximum possible one-time explosive load of 500g TNT equivalent (2,092,000 J)

- Factor in a working safety factor of 3.0

As a point of reference, the explosive load of 100g TNT equivalent is approximately equal to two hand grenades of 50g TNT capacity detonating simultaneously.

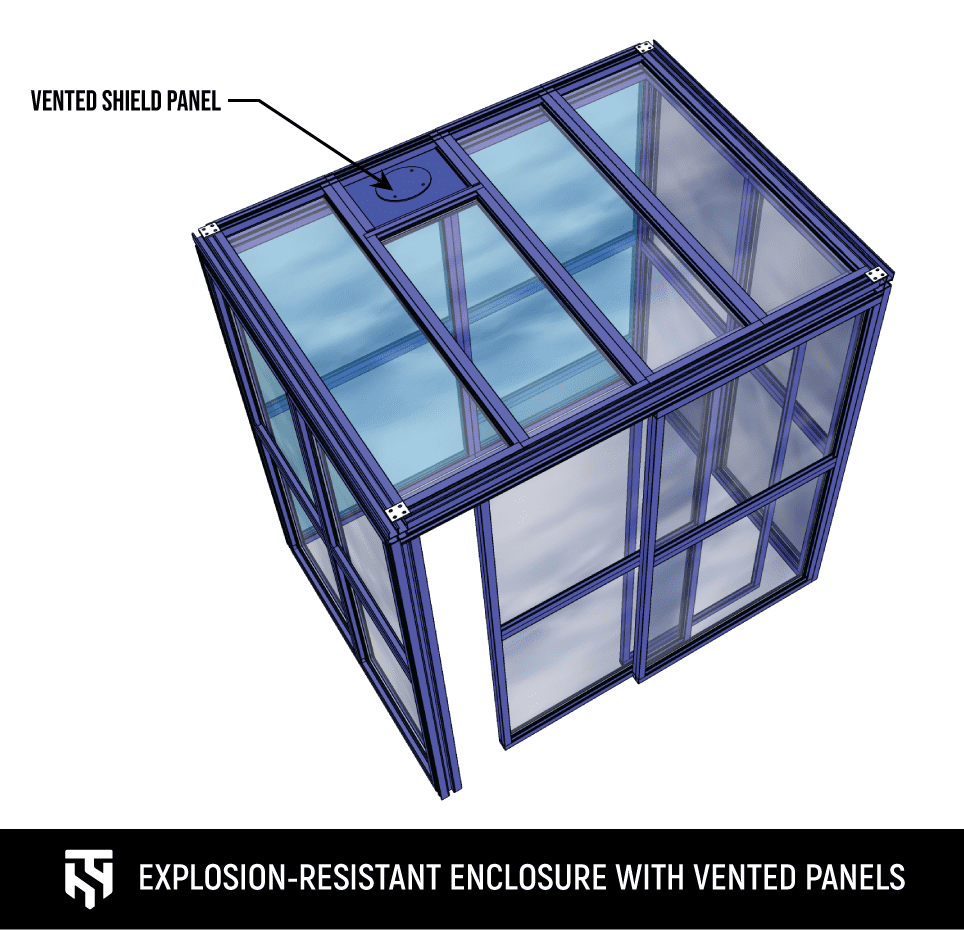

In order to meet these requirements, we utilized our proprietary framing system with 1.25” polycarbonate shielding—our most robust level of impact protection. These panels can withstand a maximum event load of 45 psi overpressure.

We also incorporated multiple vented shield panels, which will ultimately decrease the overpressure load on the polycarbonate panel surfaces and increase the overall safety factor of the room.

Designing an explosion-resistant enclosure

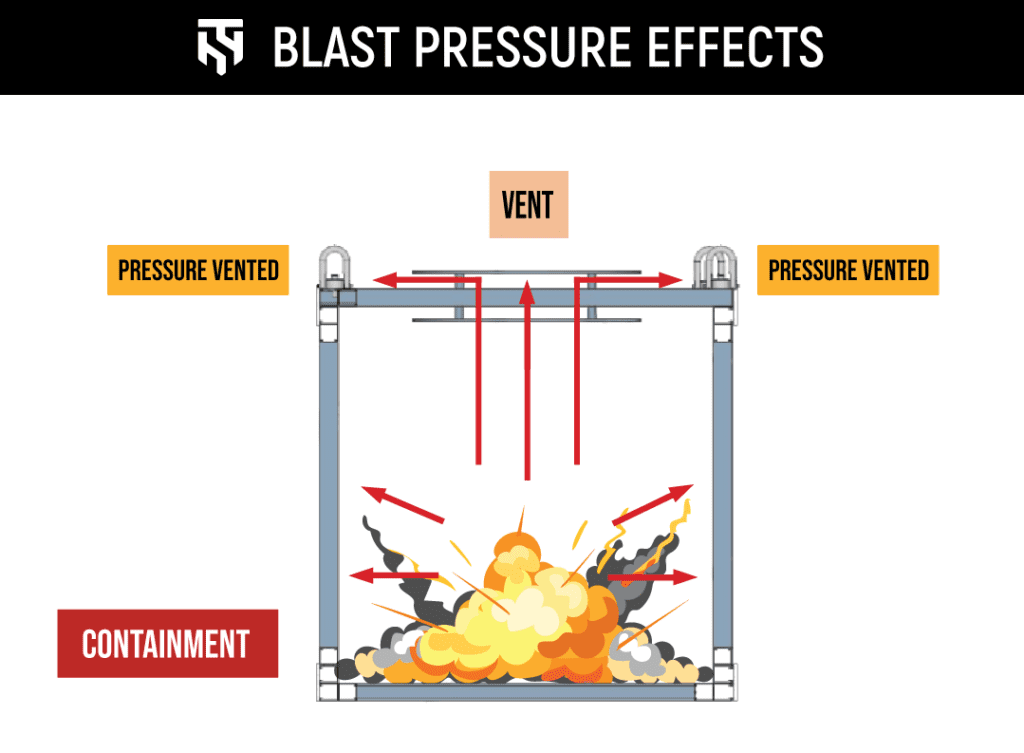

Blast waves exert pressure forces on all sides of nearby objects and structures.

For this reason, an explosive blast event should be contained with a shield room or a mobile or benchtop enclosure. Depending on the explosive load application, they can also be contained with Kevlar blankets. See the graphic below to understand better how a blast wave affects a structure.

A containment system for an explosive event should have at least five sides of protection, and sometimes our designs require all six sides of the enclosure to be shielded.

We also integrate vented shield panels to allow pressure release while keeping its full coverage protection for any projectiles that may release during the explosive event. These panels are typically placed on the top of the containment enclosure to direct the energy release upwards, away from nearby personnel and equipment.

As we mentioned, Kevlar blankets can also be used to contain explosive events. However, they can’t be designed to release overpressure. Since our customers looking to perform hydrostatic or pneumatic testing need to observe the procedure, we recommend a clear shielded enclosure instead.

All of our systems are designed to meet the specific requirements of our customers while keeping their people and machinery safe. Request a quote, and we’ll help you create a protection system for your unique application.