Centrifuges play an essential role in a wide variety of industries, including pharmaceutical, chemical, automotive, aerospace, and defense. By spinning a payload at a high rate of speed, a centrifuge can be used to simulate high gravity, or to separate solid, liquid, or gasses by density. They are also utilized in metal casting, and to test specialized equipment.

Centrifuges range in size from small desktop units that contain a payload of grams to room-size units that can accommodate payloads weighing hundreds of pounds.

We’ve had numerous customers reach us to get a fully customized centrifuge safety enclosure. Keep reading to discover the challenges of designing them.

Centrifuge Safety Most Common Hazards

Because centrifuges spin at high speeds, there is a possibility of failure and injury when using them. If the payload were to become separated from the centrifuge and shoot out toward an operator or bystander, the payload would become a ballistic projectile that could quickly become lethal.

Centrifuge payloads can eject from a centrifuge for numerous reasons, including:

- payload not secured properly

- unbalanced payload

- payload shifting

- exceeding the weight limits of the centrifuge

- centrifuge arm or rotor failing under mechanical stress

The following video shows a centrifuge failure in which the operators are lucky to escape without injuries.

Designing a Centrifuge Safety Enclosure

Centrifuge Force Analysis

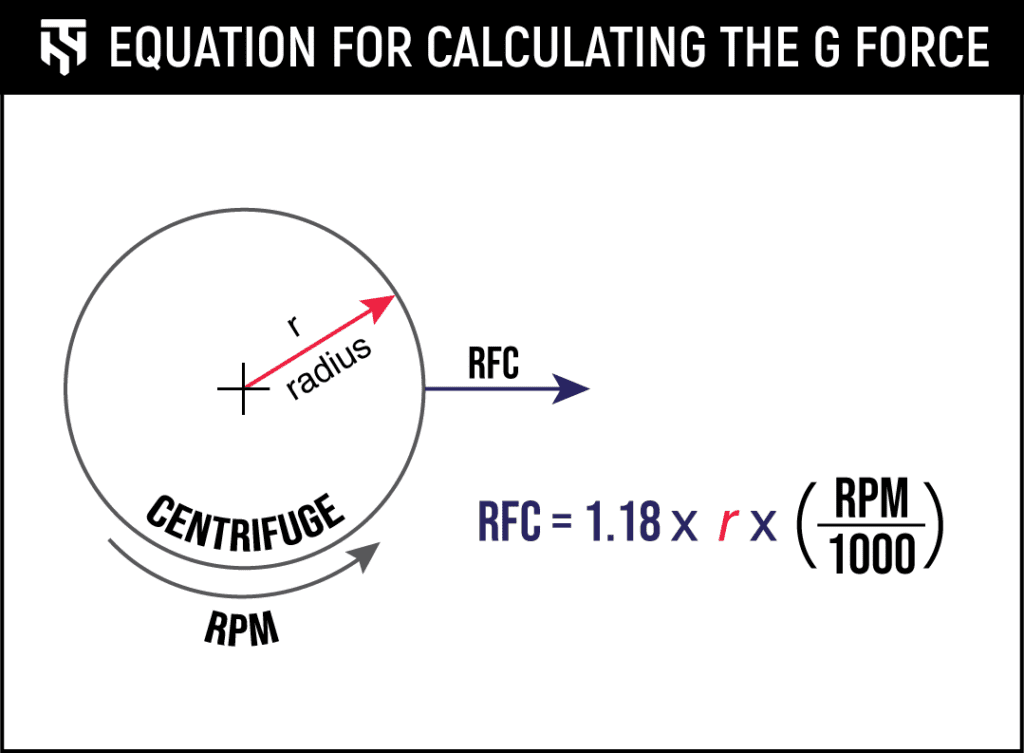

The radial force generated by the spinning rotor is expressed relative to the Earth’s gravitational force and therefore is known as relative centrifugal force (RCF) or the “g force.” The g force acting on the payload is exponential to the speed of rotation (defined as revolutions per minute; rpm).

Doubling the speed of rotation increases the centrifugal force by a factor of four. The centrifugal force also increases with the distance from the axis of rotation. The equation for calculating the RCF is given in the following image:

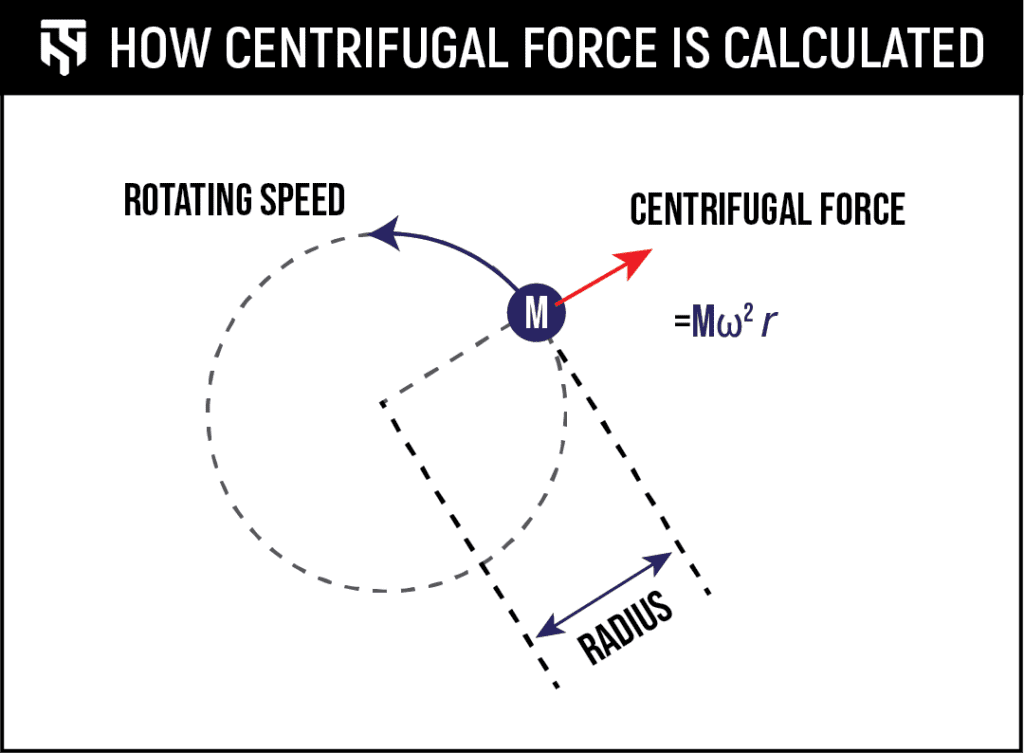

The forces generated by a centrifuge can be exceptional. The following diagram illustrates how centrifugal force is calculated. The force equals the mass of the centrifuge payload multiplied by the radius of the centrifuge arm, multiplied by the angular velocity squared, or F = Mω2r. Alternatively, if the angular velocity ω is not known, the equation can be rewritten using velocity as: F = mv²/r.

Let’s give an example of the forces that an industrial centrifuge can generate. In this case, we will analyze the Ideal Aerosmith 1231 Centrifuge System, used for military, aerospace, and industrial customers to test large payloads under simulated gravity.

This centrifuge system can accommodate a payload of 200 lbs at a speed of 400 RPM, using a radial arm length (radius) of 44 in. Converting all of these to SI units produces the following:

Mass m = 90.7185 kilograms

Radius r = 1.1176 meters

Angular Velocity ω = 41.887902 radians/second

Assuming we run the centrifuge at its highest operating limits, the resulting centrifugal force would be:

F = 90.7185 * 41.8879022 * 1.1176 = 177893.2508 N, or 177.9 kN

How much force is 177.9kN? This force is roughly the equivalent of a 2000 lb car running into a wall at 22 miles per hour.

This is a lot of force, as you can see in the following video:

Fortunately, in the case of the Ideal Aerosmith 1231, the centrifuge includes a metal enclosure to protect against some failure modes and payload ejections. As we have mentioned in our Designing Modular Machine Enclosures blog post, the metal enclosure is an example of primary containment. The Ideal Aerosmith model also includes a large hinged metal door, which is also included in the primary containment.

In a worst-case scenario, a large payload is released at maximum centrifuge speed into the door, breaking the hinges, expelling both the payload and door and breaching the primary containment. For this scenario, we have designed several secondary containment polycarbonate blast rooms to protect bystanders and operators from centrifuge failures.

Secondary Containment Analysis

At TotalShield, we perform a detailed analysis of worst-case failure modes. We engineer explosion or ballistic safety enclosures certified to contain the calculated threat based on a conservative safety factor. Designing secondary containment structures is one of the more complex analyses we perform because we must first calculate the reduction of energy and velocity associated with breaching the primary containment, and then design the secondary containment.

Our analysis of the Ideal Aerosmith 1231 utilized a conservation of momentum calculation to determine the reduction in velocity of the payload (projectile) after impacting and compromising the centrifuge door. This calculation is typically used in analyzing impact or collision events. We then calculated the energy associated with the payload at a reduced velocity outside the primary containment, and sized the secondary containment to adequately protect against this projectile, using assumptions about the maximum size/surface area of the possible payload. All of these calculations can be found in the Letter Report included with each of our custom blast mitigation products.

The image below shows a clear shielding room that we designed and installed as secondary containment for an Ideal Aerosmith 1231 centrifuge. This room provides roof access for a crane hoist to insert and remove testing payloads.

Centrifuge Secondary Containment Examples

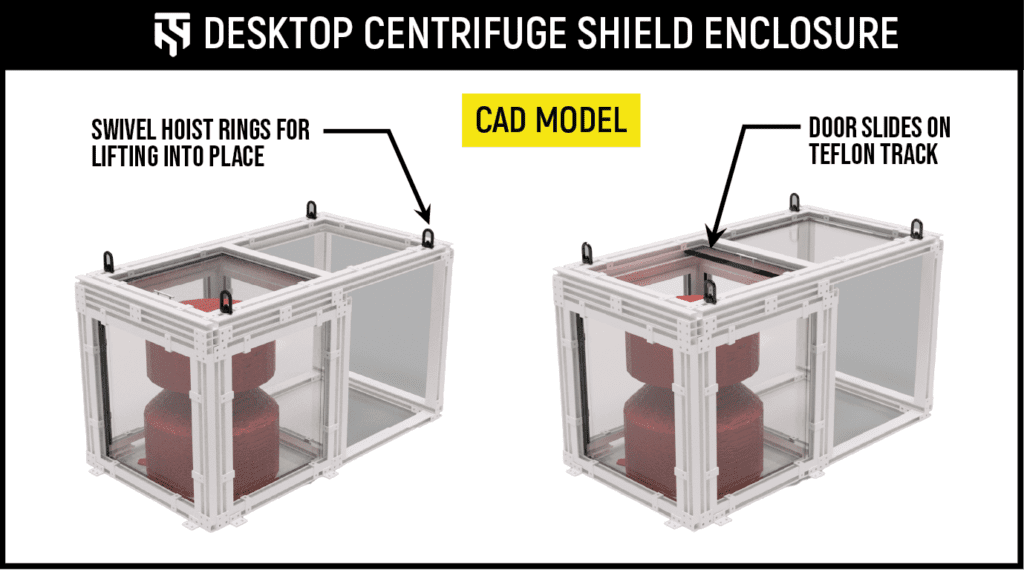

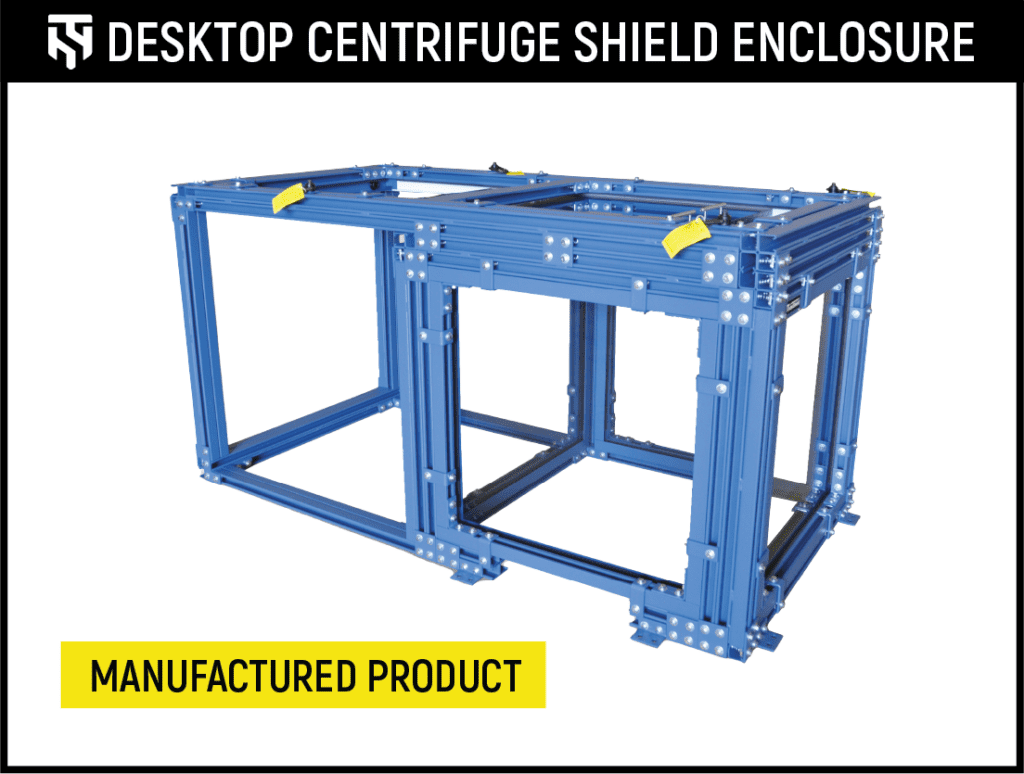

We have designed centrifuge secondary containment enclosures for both large room-size centrifuges and desktop-sized models. For example, here you can find a CAD model of a desktop centrifuge shield enclosure, and right next to it the manufactured product.

A somewhat larger centrifuge for which we have designed secondary containment is the Ideal Aerosmith 1571P Test Table with Thermal Chamber. This centrifuge has a maximum rotational speed of 3,000 RPM, primarily used in the development and/or production testing of inertial packages for missile systems.

Due to the stand-up nature of the centrifuge, our customer desired a polycarbonate shield room for secondary containment.

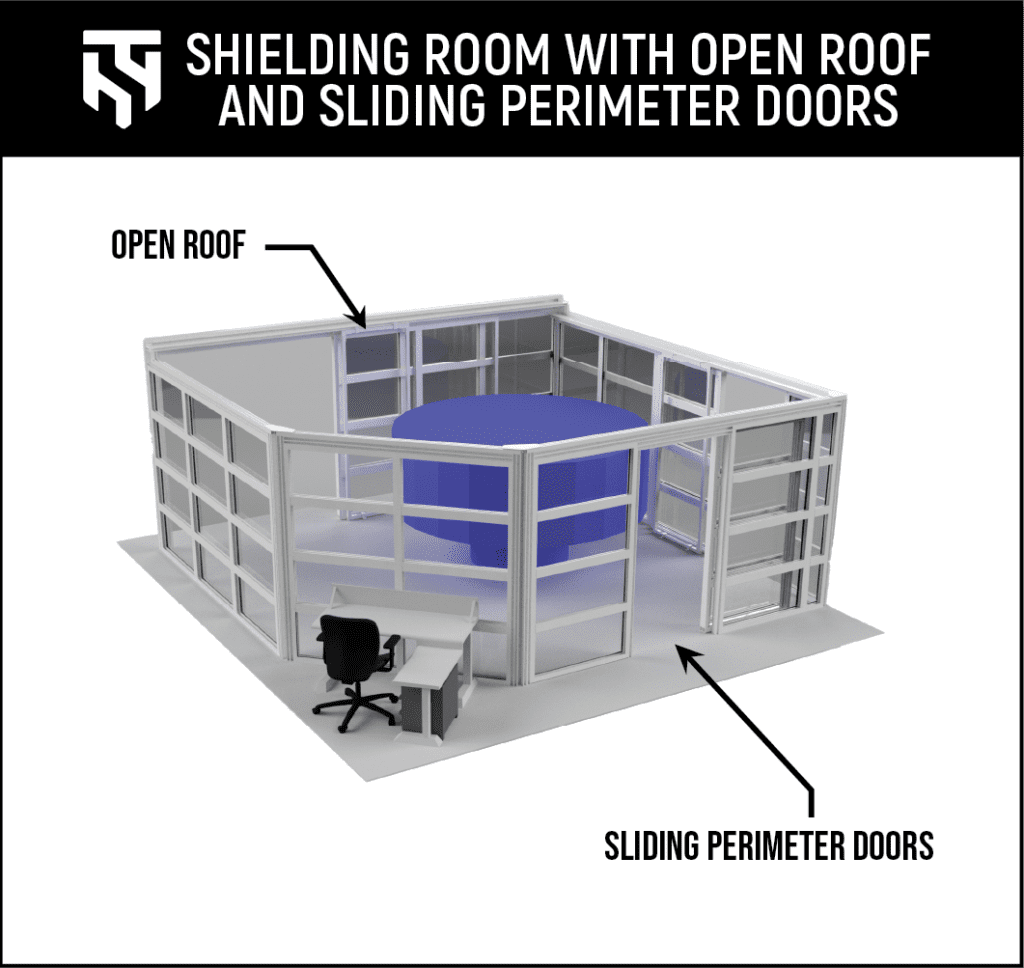

Some of the largest secondary containment shielding rooms are for aerospace and defense contractors that utilize large centrifuges that take up significant room areas. The image below shows an open-roof design with sliding perimeter doors.

Industrial Centrifuge Safety: Conclusion

Centrifuges play a critical role in various industries. However, their high rate of speed poses a risk of injury to the personnel that works around these machines. While they typically include a primary containment housing, they can fail due to the extreme forces involved in operating centrifuges.

TotalShield is the worldwide expert in designing secondary containment and safety enclosures for centrifuges of any size – from small benchtop centrifuges to room-sized centrifuges. If your organization uses high-speed centrifuges and you want to explore safety enclosures, don’t hesitate to call us!